Microelectronics

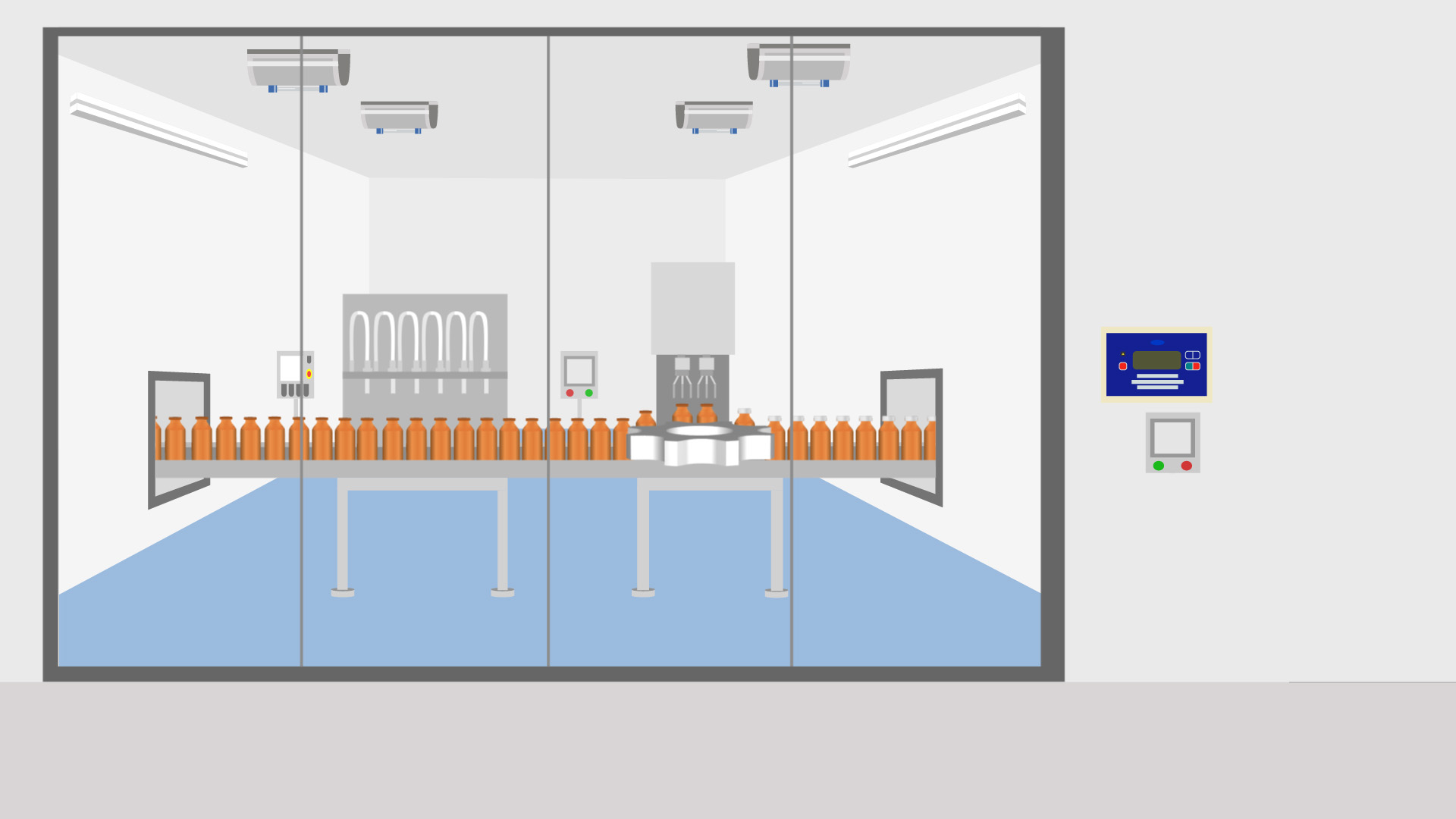

Most cleanrooms under construction in the world belongs to microelectronics. Rapid technologies development in the microelectronics industry leads to a constantly increasing need for cleanrooms, which are subject to very strict requirements for air and surfaces cleanliness in production areas. The topological microcircuits size decreases every year and therefore it becomes more difficult to prevent their damage and microbiological contamination during production, which can lead to defects. Therefore, the suitable products percentage directly depends on their contamination degree.

The specifics of infectious safety in the microelectronics industry

- Necessity to create aseptic conditions for microelectronics production;

- Constant confirmation of the room cleanliness class;

- Required monitoring of the microelectronic products manufacturing process (content of microorganisms and viruses on the products surfaces, in the air and on the room surfaces);

- Measures / protocols to prevent the products and manufacturing facilities contamination by microorganisms and viruses;

- Risk of introducing microorganisms and viruses with cargos delivered to the cleanroom;

- Possibility of cleanrooms and microelectronic products contamination with human pathogenic microflora;

- Possibility of cross-contamination among the working personnel with infections and viruses.

The specifics of disinfection measures in clean rooms of microelectronics industry

- Need for repeated disinfection to preserve and constantly maintain microbiological purity with the 99.9 % or more efficiency;

- Limitations for using most chemical disinfectant classes and physical disinfection methods under conditions of continuous production cycle;

- Corrosive effect of the used inventory and equipment on working surfaces;

- Lack of official regulations on scheduled and emergency cleanrooms disinfection, especially in cases of identifying various "undesirable microorganisms".

Pulsed ultraviolet units allow the microelectronics factories to successfully cope with a whole number of problems:

- Disinfection of microelectronics factory premises with 99.99 % or higher efficiency within shortest time;

- Rapid disinfection of a large rooms’ number within one working shift during a routine break, without disrupting the work schedule;

- Ensuring microbiological cleanliness of products and production facilities, including inactivation of such microorganisms and viruses that are highly resistant to traditional disinfectants, i.e. mold and yeast fungi, highly resistant viruses;

- Increasing the products shelf life;

- Reducing financial losses associated with losses during production, returns from buyers and users;

- Individual and collective protection of patients and working staff from bacteria and viruses, including the new SARS-COV-2 coronavirus;

- Financial expenses’ reduction by avoiding payments for temporary disability certificates of the personnel, as well as for the infection foci elimination;

- Enhancing the manufacturer image as an organization that cares about providing high quality services by ensuring the infectious safety of visitors and staff.

Choosing our products, you get the optimal solution for guaranteed highly effective disinfection of premises of microelectronics industry enterprises, including cleanrooms of all cleanliness classes; increase the microbiological safety of manufactured products, equipment, the premises itself and working personnel and, as a result, ensure the basic principle of clean rooms standards – “Quality as part of the design”

We are convinced that pulsed ultraviolet units used in various areas, including microelectronics industry companies, not only during the COVID-19 pandemic and seasonal outbreaks of other viral diseases, but also in "peacetime" are not a luxury, but a necessity that is here to stay.

Select the unit

* - Fields with an asterisk are required.